Two Upgrades to Boost Your Leather Splitting Machine

Time to upgrade your splitting machine? Does the tannery next door have a shiny new Mosconi in the driveway? Maybe they went with the sleek new Alpe-Spak? In either case, you and I both know your tannery owner (or maybe accountant) won’t let you spend that kind of money on something like that!

I can hear it now, “There’s nothing wrong with our 1986 Mercier…it runs just fine!”

Ok, so you’re stuck with the rusty old Dodge Caravan of leather splitters. Maybe it can still get the kids to school and back, but it would make the drive more manageable if you could put in a new stereo with Bluetooth, maybe a GPS.

Bolt-On Upgrades to Update Your Leather Splitting Machine

The good news is that some of the latest technology for splitting machines is available as a bolt-on to your older machine. This gives you access to features not in existence when your machine was made.

Here are a couple of examples of bolt-ons you can invest in to upgrade your current splitting machine:

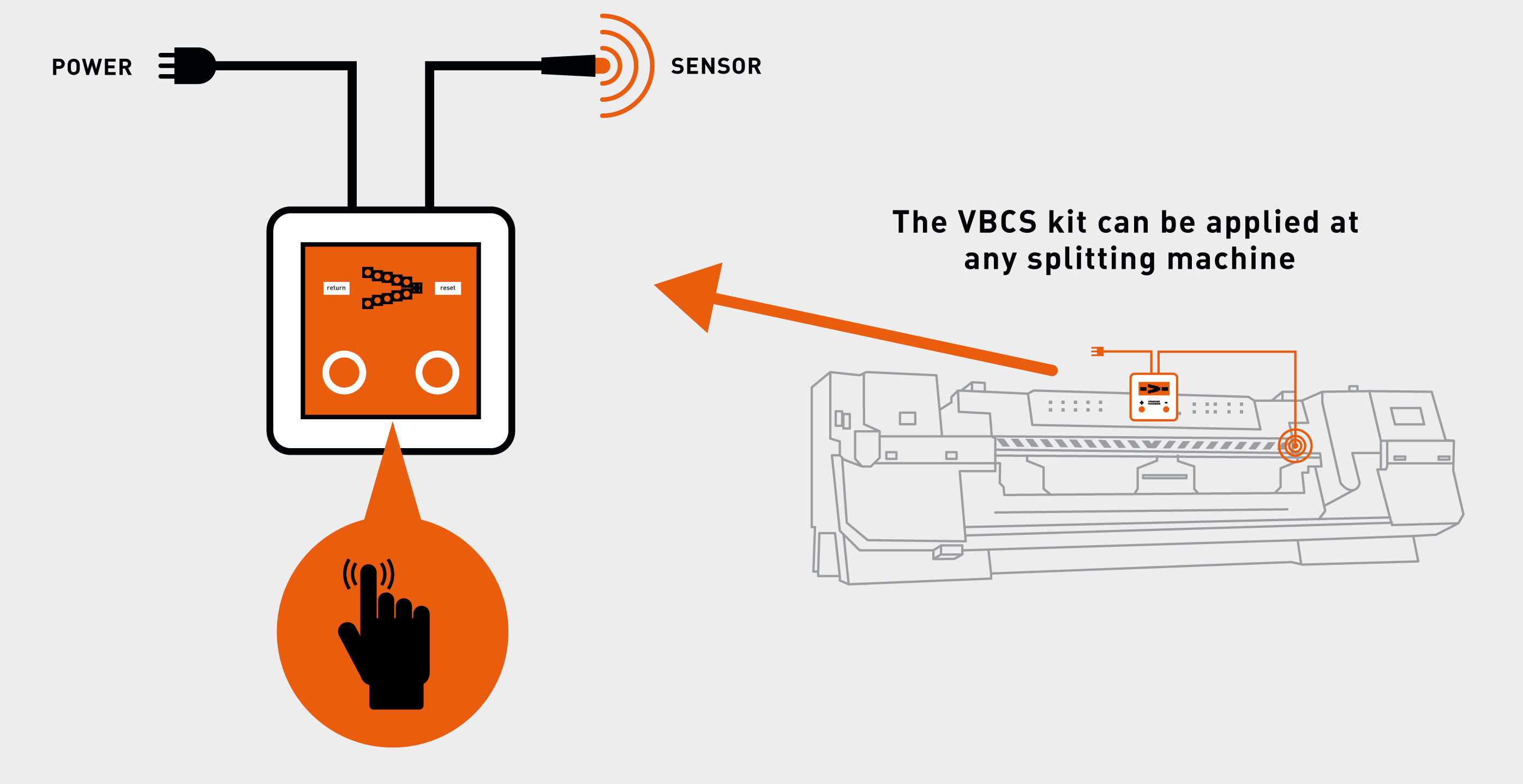

1. Visual Bevel Control System

This system is optional on many new models. It uses a sensor to measure bevel dimensions and alert the operator of any change in the bevel of the splitting knife. Newer machines allow you to have the machine adjust the stones to automatically compensate for it.

In the aftermarket case, the operator has a display indicating if the bevel is good, heavy, or light. The sensor technology for this version is the same as the ones fitted on the new machines. Only the display is different.

It’s like the difference between having your new car equipped with factory navigation, or putting a Garmin in the Caravan!

Cost: Less than $3,000 USD

2. Feeding Brake

This system is perfect for lime splitting. The operator’s job is hard, since the hide is slippery and difficult to handle. The feeding job requires the operator to open the wrinkles as the hide enters the machine by pushing down on the central part of the hide with their hands. The feeding brake is a pneumatic arm located above the feeding table that activates once the hide is introduced. The pneumatic arm takes the place of the operator’s hands allowing them to prepare for the next hide.

While this device may not improve the feeding quality, it takes a lot of the work load away from the operator and allows them to prep the next hide before the previous hide has fully entered the machine. This could improve productivity by up to 20%.

…Let’s call this one the Caravan Turbo Charger!

Cost: About $4,500 USD

These bolt-on upgrades are just two options to make your older machine work with a little more efficiency and accuracy. As you can see, the cost is not prohibitive and you can pick and choose which one will work best for you.

They will not, however, make a poorly maintained machine run any better. You can program a route into the Garmin, but the Caravan won’t get there if the tires are flat!