Streamlining Success: Implementing the 5S Program Across our Facilities

At First Source Worldwide, our unwavering commitment to excellence fuels every aspect of our operations. This dedication is exemplified through the implementation of 5S across our sites. 5S is defined as a methodology resulting in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It’s designed to help build a quality work environment, both physically and mentally.

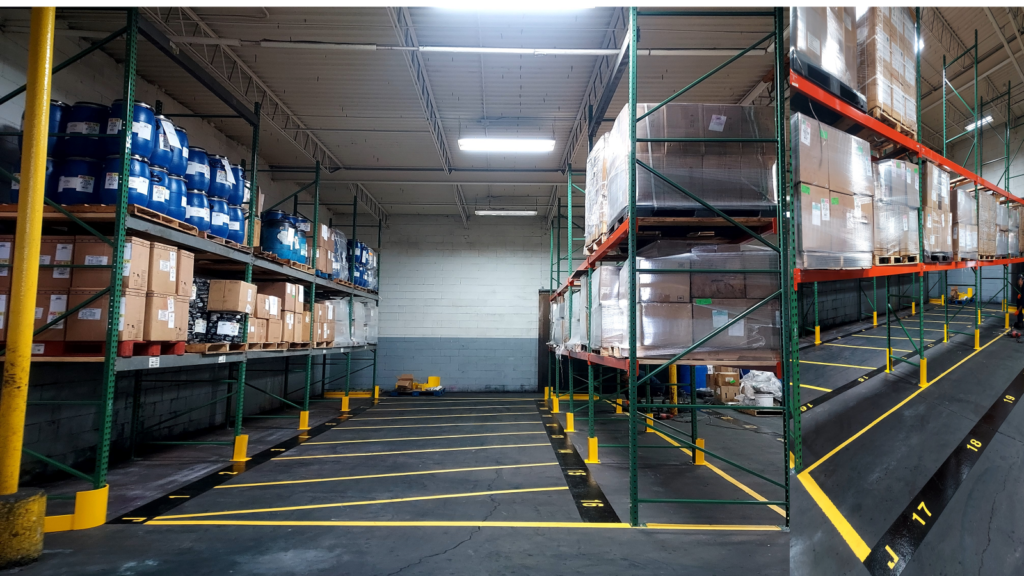

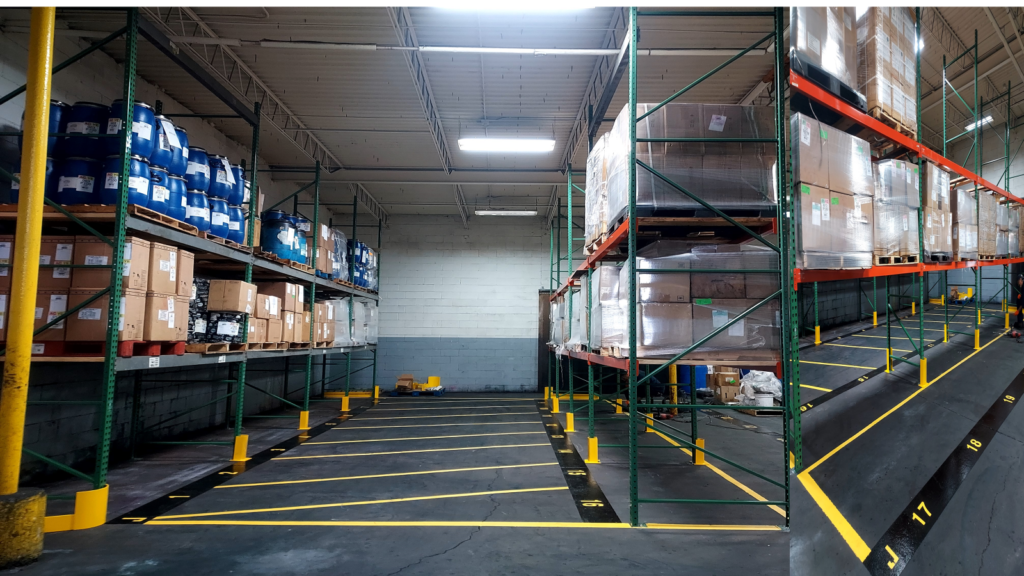

This philosophy of 5S extends beyond mere production floors; it permeates every corner of our organization, from visual control to lean production areas. Recognizing that the condition of our workspaces speaks volumes about our commitment to excellence, we prioritize maintaining impeccable 5S standards. After all, these standards not only shape our employees’ experiences but also serve as the bedrock of our customers’ initial impressions.

Goal = “Best In Class” for Performance, Safety & Customer Image!

The 5S quality tool is derived from five Japanese terms beginning with the letter “S” used to create a workplace suited for visual control and lean production. The English language pillars of 5S are simple to learn and important to implement:

- SORT: To separate needed tools, parts, and instructions from unneeded materials and to remove the unneeded ones.

- SET: To neatly arrange and identify parts and tools for ease of use.

- SHINE: To conduct a cleanup campaign.

- STANDARDIZE: To develop daily routines to maintain a workplace in perfect condition.

- SUSTAIN: To form the habit of always following the first four S’s, by auditing: “Inspect what you Expect.”

SORT

The Sort step separates items in your workspace that you know you need from those that you do not need or may

not need by moving the “un-needed” to a “red tag” holding area (place for people to browse latter or dispose).

Why Do You Need Sort?

- Sort enables you to have a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up the space to be used for other things.

How Do You Implement Sort?

- Separate necessary items (e.g., tools, parts, and materials) from unnecessary items. Recommend sorting items into four categories:

- Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will stay in this work area.

- Items needed in another work area. Essentially, these are misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to whomever is responsible for that work area.

- Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with tags, which at a minimum, should include the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage the area.

- Items you do not need. These are items that you are 100% confident are not needed. They should be immediately discarded.

SET

The Set step thoroughly organizes the items that remain after sorting, such that frequently used items are easy to access and every item has a clear and easy-to-find home.

Why Do You Need to Set?

- Set enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion as items are placed in more ergonomic locations. It is also the second step towards opening up space to be used for other things.

How Do You Implement Set?

After you’ve sorted items, it’s time to decide how you want to organize them. Recommend the following methodology:

- Provide easy access to frequently used items. The key to reducing waste from excess motion is to place frequently used items within easy reach.

- Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- Visualize item homes. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- Use containers. If it is appropriate for the type of item, consider organizing it within a container.

- Label items. If an item is too big to put into a container, find a place to store it and put a label on the item / area.

- Be agile. Your initial set pass will likely deliver a significant improvement – but you are also likely to overlook some potential improvements. Meet with your team after one week and again after two weeks to brainstorm further improvements as part of your initial implementation.

SHINE

The Shine step improves the work area by thoroughly cleaning and inspecting tools, equipment, and other items.

Why Do You Need to Shine?

- Shine creates a work environment that engages and empowers operators by giving them more responsibility over their work area. It also helps them to identify problems before they interfere with production. For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How Do You Implement Shine?

After you’ve set items, it’s time to elevate the work area by cleaning, inspecting, and in some cases performing routine maintenance. Recommend the following:

- Clean…Clean…Clean. Using appropriate cleaners and cleaning tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory.

- Find the source. The guiding principle of this step is “clean to understand.” If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair.

STANDARDIZE

The Standardize step is a bridge between the first three steps (Sort, Set, Shine) and the last step (Sustain).

In this step, your goal is to capture best practices for 5S as standardized (pictures & checklists) work for your team.

Why Do You Need to Standardize?

- Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How Do You Implement Standardize?

It’s time to make sure all your hard work continues to pay dividends into the future. Set expectations for the future with a documented 5S process. To do so, we recommend that you:

- Capture the essence. Focus on the important things! Capture the essence of each task and no more. Otherwise, your documentation will very likely not be maintained.

- Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is to have a name for each task that serves as a quick reminder and a more detailed description for training.

- Organize to simplify. Organize your checklists by role, by shift, and by frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

- Final Picture of Standard: Post a picture of how the area is to look (clean, organized, labeled, etc.).

SUSTAIN

The Sustain step assures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks through Empowerment & Accountability.

Why Do You Need to Sustain?

- “Inspect What You Expect” on 5S processes to lock in your gains and ensure further and continued progress.

How Do You Implement Sustain?

Once you’ve standardized, it’s time to continually act upon those standards.

- Create a schedule. Develop 5S practices as scheduled tasks (by role (production & supervision), shift, and frequency).

- Teach through demonstration. Instruct employees on how to conduct 5S tasks through demonstration and training. Showing employees what is expected of them will prepare them to complete tasks on their own.

- Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off the wagon, so patiently and helpfully offer corrections when necessary.

- Adapt as necessary. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

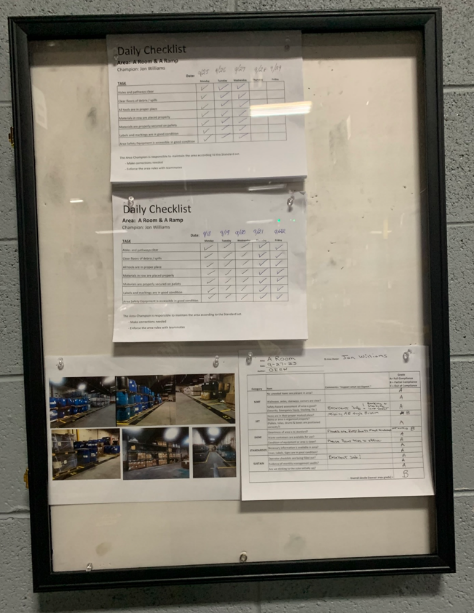

Presentation Case – in each common area

- Area Standard Pictures (what is it supposed to look like)

- Weekly Champion Checklist (daily sign off)

- Management Audit (12-month retention)

Low Cost – High Visual Impact

- Selection of proper cleaning tools (brooms, dust pans, scrappers, floor dry, etc.)

- Labeled area (tool bar to hang up items), tool shadow boards, or containers

- Paint: Floor markings, Aisle lines, Aisle locations

- Items in area marked out on floor / wall (garbage, equip, etc.)

- Broken pallet replacement, Small pallet replacement

- Broken powder bag repack into drums for internal use

- Drums need pallet straps

- Boxes higher than 2, need shrink wrapping

- Presentation Display Cases – hung in local area (can combine some areas)

In conclusion, at First Source Worldwide, our steadfast dedication to excellence is the driving force behind all our endeavors. This commitment is vividly demonstrated through the comprehensive implementation of 5S methodology across our sites. 5S is not merely a set of principles but a philosophy deeply ingrained in our culture.

As outlined in the 5S methodology, each step—Sort, Set, Shine, Standardize, and Sustain—plays a crucial role in ensuring the efficacy and longevity of our efforts. Through meticulous sorting, thoughtful organization, rigorous cleanliness, standardized processes, and ongoing commitment to sustainability, we create an environment conducive to continuous improvement and success.

Moreover, our approach emphasizes low-cost solutions with high visual impact, ensuring that even the smallest details contribute to a workspace that is both efficient and aesthetically pleasing. From proper cleaning tools to presentation display cases, every element is carefully considered to maximize efficiency and effectiveness.

In essence, the integration of 5S methodology at First Source Worldwide is not just about improving our physical workspaces; it’s about fostering a culture of excellence, empowerment, and accountability. By embracing these principles wholeheartedly, we pave the way for sustained success and unparalleled customer satisfaction.