Finishing Line Upgrades to Save Time & Reduce Consumption – Part 1

Let’s take a look at your spray finishing line to see if it’s performing up to standard. You’ll probably notice room for improvement, even if your line is only a few years old. Of course, the older it is the more likely its in need of an update or intervention.

There’s a wide variety of spray lines working in leather today. In this series we’ll focus on two “bolt on” items that we can retrofit onto 90% of the equipment found in tanneries within the past year. In Part One, we’ll look at a one of these two bolt-ons: the quick color change system. Because variables such as conveyor system, working width, ventilation, spray gun type, finish type, and substrate all play a part in the final equation, I will keep this discussion quite general in nature.

Adding a Quick Color Change System to Your Spray Lines

A quick color change system can be retrofit onto most spray lines. The good news is that the more you invested into your existing line, the less you’re likely to spend to make this update. A line installed or updated five years ago may already be equipped with the basic hardware. Whereas a 20-year-old line may need a full retrofit. Even in the worst case scenario, the return on investment is still quite attractive.

The quick color change system allows the operator to change a spray line’s color without the down time associated with cleaning of pumps, lines, or guns. An operator prepares a color in a mixing tank or drum in advance. Then, they change to the new color without stopping the line and production continues without missing a hide.

The software even allows for a sample hide to run through the booth in the middle of a production run!

Calculating Return on Investment

How much does such a system cost and what kind of return can you expect on your investment? It depends on:

1. The cost of upgrading your particular system.

2. The amount of time currently spent on color changes.

Calculating the cost depends on what you’ll need in an upgrade. Many components make up the complete system. After a full assessment by a technician, you’ll see an accurate quote. As an idea, it could cost less than $10K, or $25K and up.

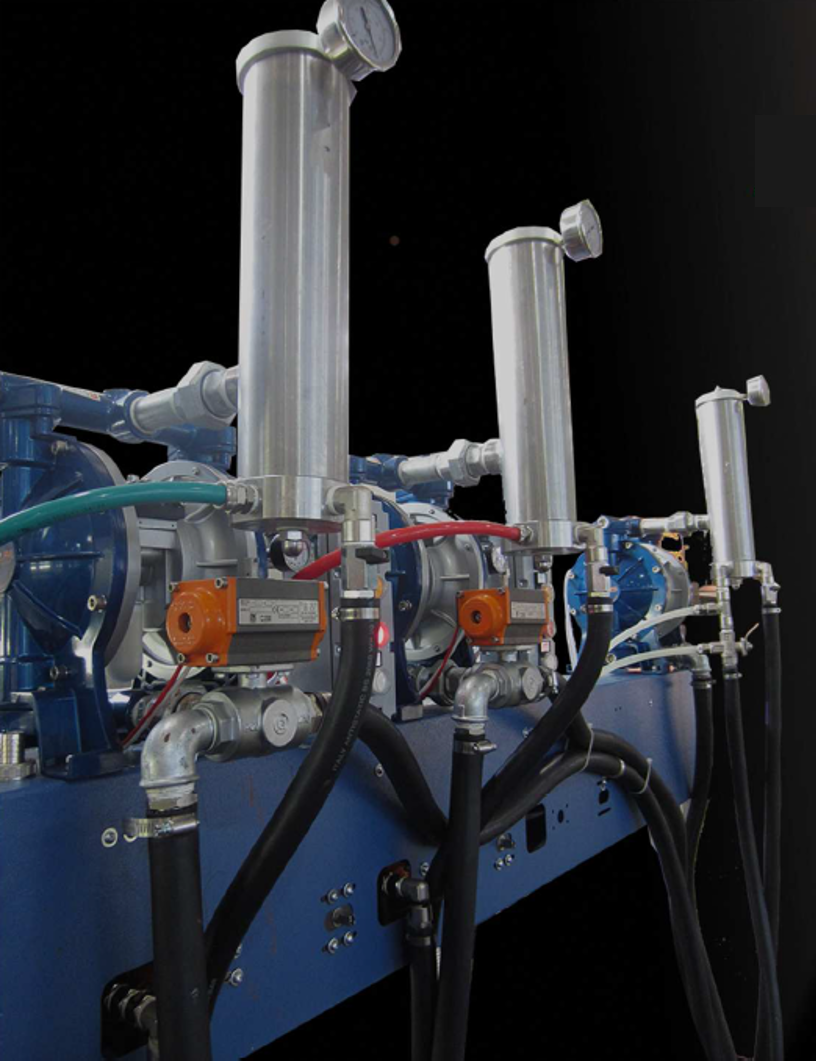

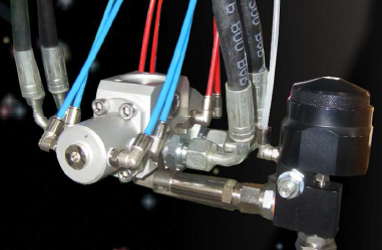

The control interface, processor, and software are at the heart of the system and will replace the ones that came with your spray line. The system also requires that your rotary arms have two spray guns mounted on each arm (this is quite common). Other components to consider are prep tanks, pumps, lines, valves, and the rotary joint (the main carousel).

After installing the parts necessary to run the new system, you’ll have instant color change without fear of contamination or cleaning time.

Request Your Assessment to Change Color with Ease

Our technicians are well versed in tannery operations. We provide assessments to review your equipment and see what you’ll need to add this bolt-on system. Final cost will differ, but savings will be a reflection of your current operations and the efficiencies you’ll gain.

You can measure savings in time and space. If you run one color, twelve hours a day, seven days a week, you probably haven’t read this far down the page. For most finishers, it’s not uncommon to change colors several times per day. Each change takes time and costs money. I’ve worked with tanneries with three lines, but only run at any one time because the third is in cleaning and prep for the next color. In a case like this, you can even eliminate one full line! At the very least, you’ll be saving hours and increasing your production potential.

You can measure savings in time and space. If you run one color, twelve hours a day, seven days a week, you probably haven’t read this far down the page. For most finishers, it’s not uncommon to change colors several times per day. Each change takes time and costs money. I’ve worked with tanneries with three lines, but only run at any one time because the third is in cleaning and prep for the next color. In a case like this, you can even eliminate one full line! At the very least, you’ll be saving hours and increasing your production potential.

At this point, it should be clear that I can’t provide an accurate evaluation of how much upgrading your spray line to the quick color change system will cost. I also can’t describe how much this system could save you. I encourage you to contact us and set up a consultation to review your line and see what’s possible.

Stay tuned! In Part Two, we’ll look at the advantages of updating your economizer to reduce overspray. In the meantime, check out these other great posts on maintaining your tannery equipment.