How to Choose the Best Dye Tests for Your Lab

How do we test dyes? This is a trick question…

I could write an encyclopedia of all the different dye tests and application requirements. To make it simple, I like to think of dye tests in two categories: general and specific. The general tests are routine; performed for most dyes. Specific tests relate to a certain dye type, application, or industry. Let’s look at the commonalities of general tests and the careful R&D work that goes into specific tests.

General Dye Tests

For the most part, lab technicians should be familiar with a few basic dye laboratory tests. These are a few of the most common tests.

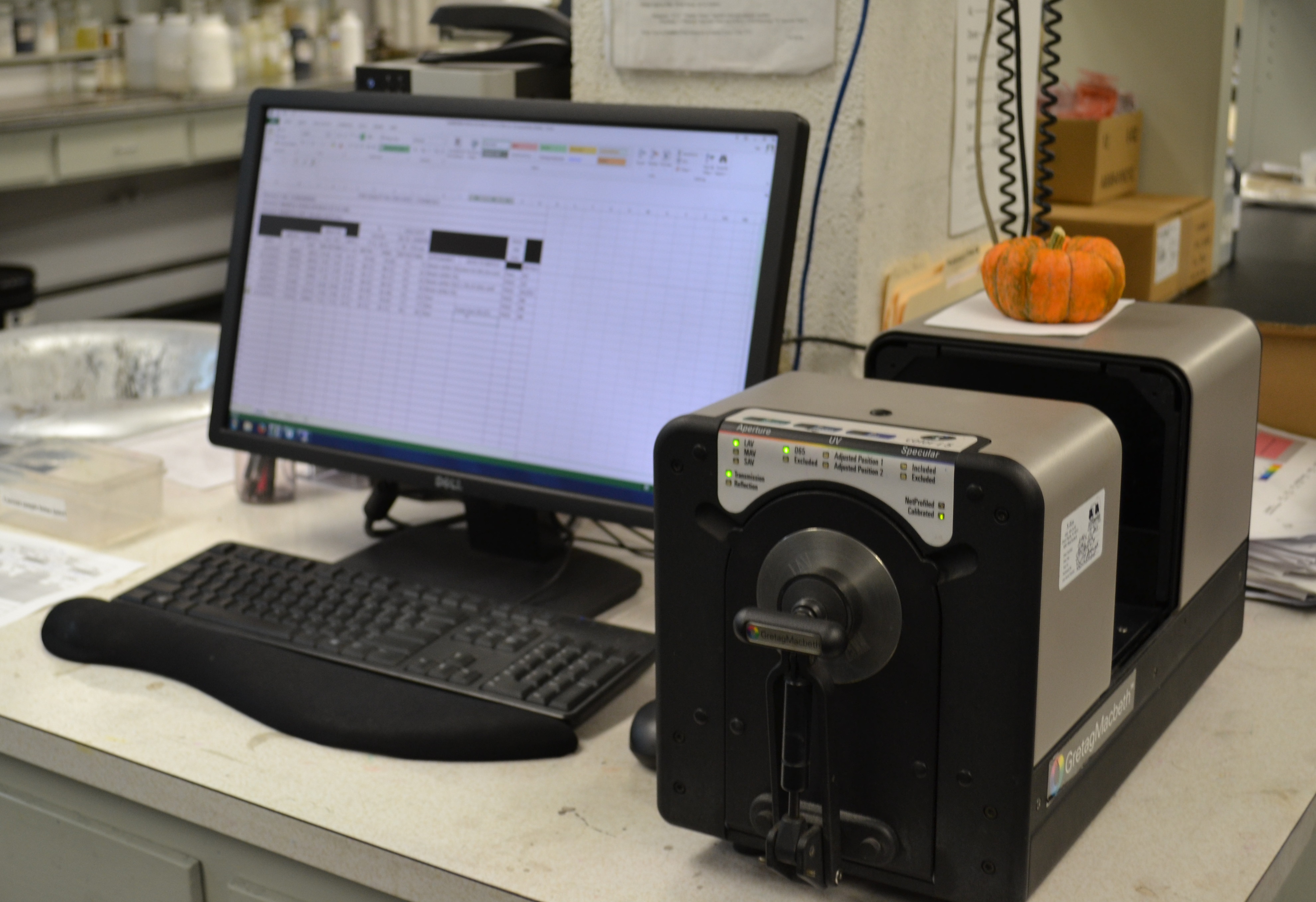

Spectrophotometer Transmission Readings

One of the first tests performed is often a transmission test. Transmission tests show strength and shade readings of a dye. Technicians usually use a spectrophotometer to get these readings. This instrument measures the curvature across the visible spectrum. Comparing the two curves of the sample and the standard is what tells us if the dye is in-shade or off-shade.

This test is critical. If the shade and strength are off, the dye is out of spec and should either be adjusted or not used.

Solubility in Water

In addition to the spectrophotometer transmissions, you’ll also want to run a solubility test. In this test, a technician dissolves the dye in water, then heats it. After, the solution is filtered using #2 Whatman paper.

As the solution passes through the paper, the technician monitors the amount of time it takes to pass. At the end of the time period, the technician also logs the amount of residue left on the filter paper. We then use these two factors to measure against the standard.

Other General Tests to Consider

Particle Size Test

Particle size may be important for certain applications for quality, usability, dispersion, coverage, and other factors. Test a sample against a standard when needed.

Dust Test

A dust test uses a cylinder and a wet piece of filter paper to see if the dye needs dedusting. This can be critical if you want a no-mess dye solution, or to maintain air quality.

pH Test

pH is an important factor in evaluating dyes that can have a negative impact on batches down the line. I spoke about this in detail here.

Specific Dye Tests

In order to determine if a dye is suitable for an application, you’ll have to go beyond the general tests. While some general tests can be more or less important for a certain industry, the specific testing is where we can nail down which dye is best for its intended use. Here are two examples of industry-specific tests:

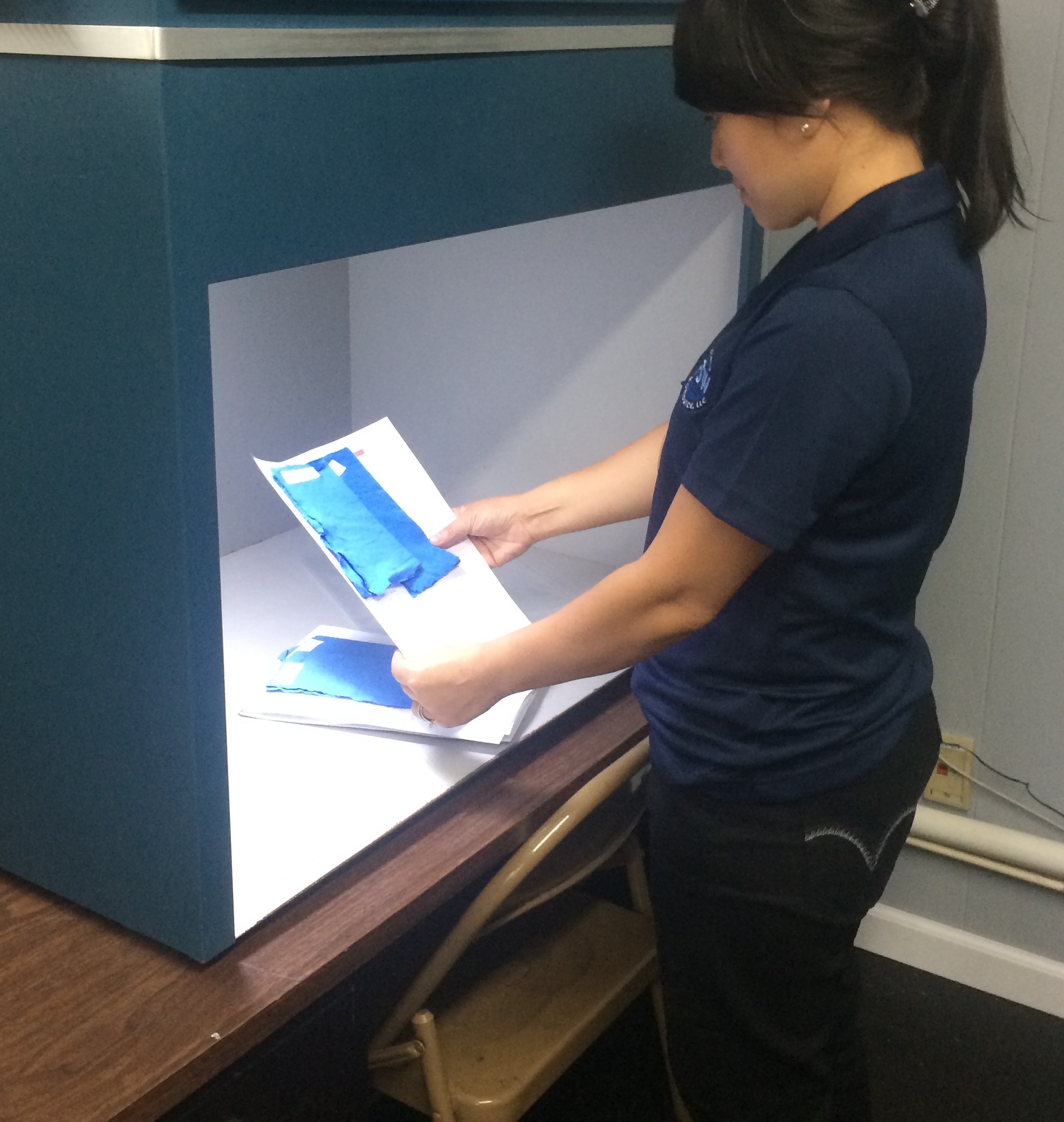

Dyeing Textiles or Coloring Paper

Dyes for use in coloring textiles need to be tested on a piece of fabric at a designated concentration. There is no truer test than seeing the color in its intended application. Even dyes that pass initial general tests can fail when dyed out, so it’s important to do runs for visual performance or other factors, like wash fastness.

The same holds true for the paper industry. When coloring paper (or other substrates like wood or metal), it’s common to run tests on the wood pulp used in production to see how the dye performs. Here again, a visual test is best.

See our tips for running visual tests here.

There are many different ways to test dyes for specific end uses, it would be impossible to list them all. In fact, some companies develop their own tests to make sure the dyes they use meet their needs and those of their customers. We should always keep in mind that while the general tests are the beginning, the specific tests for certain substrates are the most important.