How to Make Washable Leathers

Washable leathers tend to be soft leathers used in garments or products prone to repeated cleanings. It seems contradictory that you could be able to wash leather; the norm is to prevent water from damaging something like a leather shoe or handbag. But, with special treatment it is possible to make leather washable. More so, washable leather that maintains its original integrity in size, color, and texture.

Start with a Pretreatment of Sortan TFG

To produce a washable leather, we first select a superior glutaraldehyde tanning material. Sortan TFG is the best for this application from FSW’s line of products. This product is capable of crosslinking proteins since it has a bifunctional nature. We can use it as a complementary tannage to chrome tannage. Incorporating a glutaraldehyde tanning product, we’ll see better protein fiber stabilization. This means the leather will have a higher shrink temperature and better resistance to chemical products (like laundry detergent).

Sortan TFG can be applied to leather at the same pH range as chrome tanning and retanning. An added benefit for washable leathers, Sortan TFG also has a softening effect. Using this aldehyde tanning agent makes leathers more receptive to chemical treatments for washability, perspiration, and other specific effects. We can use Sortan TFG as both a retanning agent and as a supplementary material to other tannages.

Select Homogenous Dyes for Vibrancy

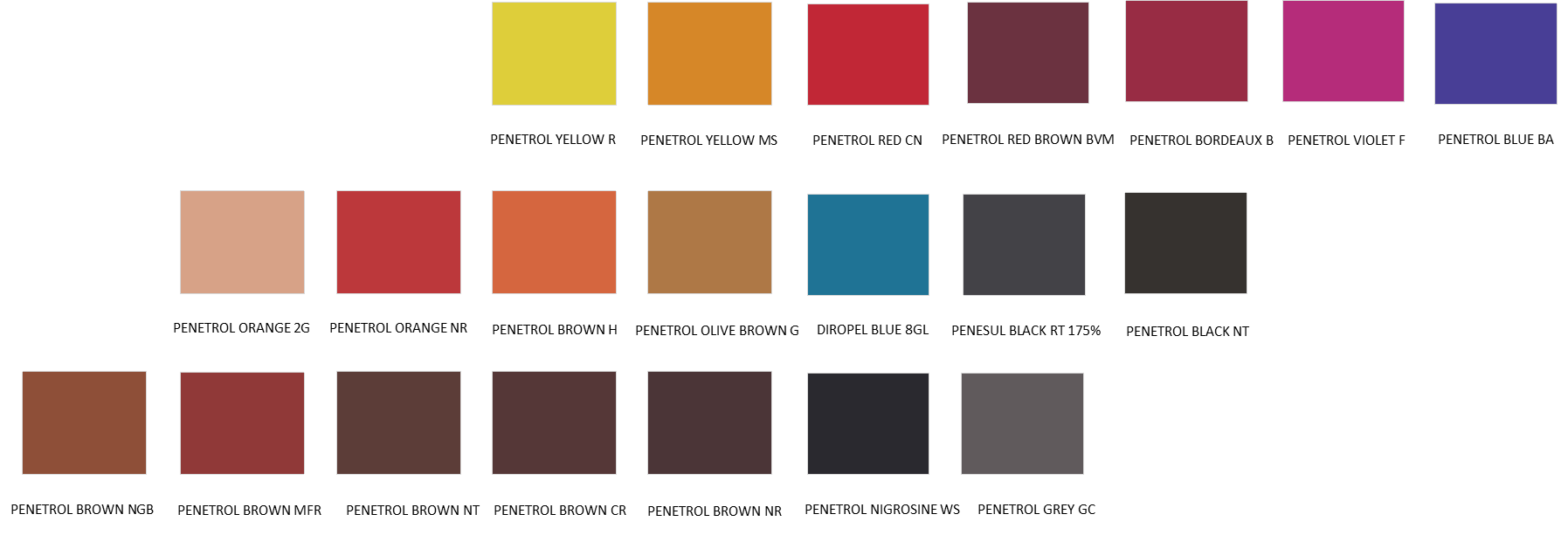

Next, choose dyes with excellent coverage effect, enhanced leveling and low migration properties. FSW’s line of Homogeneous Dyes suits these needs well. They also provide good performance in lightfastness, perspiration, and washing and still produce a vibrant color. You’ll see the homogenous dye colors below.

Fatliquoring to Lock-in Leather Softness

When we use an oil on leather it’s important to match the oil’s application properties with the type of leather we’re working with. Through careful selection for the conditions, the fatliquoring process will lubricate the leather fibers.

In the neutralization process, we recommend a pH of between 4.7 – 4.9. After neutralizing and dyeing the leather, then we can apply the fatliquor. For washable leather, we recommend an emulsified synthetic oil like FSW’s Meropol Oil WPS. This oil brings softness, resistance to yellowing, and a strong binding to the leather fiber structure. Plus, it has high heat resistance. After applying, the final treatment will be to use metal salts to fix the oil to the fibers.

These characteristics make Meropol Oil WPS suitable for washable leathers. This oil is substantive to mineral tanned leather, which allows for the softening common for washable leathers. This new synthetic oil is growing in popularity among tanners due to the wider range of properties it provides.

The chemistry behind washable leathers has become more popular as they increase in market demand. Washable leather allows consumers to care for their leather products at home without risk of damage. They also encourage regular use and investment in the product. If you’re looking to improve the quality and performance of your washable leather products, contact us today for technical support.